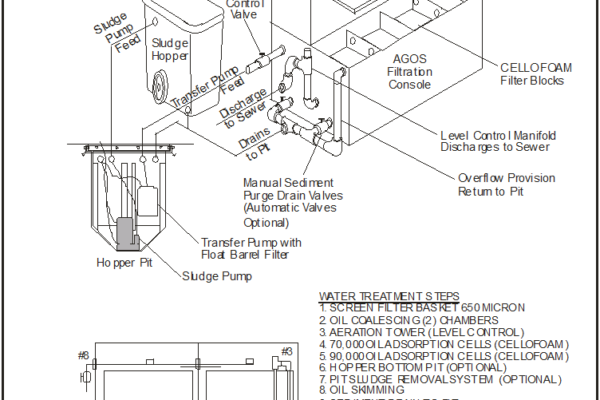

Operating on 115 VAC, this system uses a Submersible Sump Pump mounted inside a Barrel Filter to pump the water from the pit and into a set of large tanks mounted at the back of the console. The rear tanks have oil coalescers which force free floating oils to float to the surface where the oil can be skimmed off through a bleed-valve and into a bucket or an optional oil collection barrel. Leaving the oil coalescing sections in the rear of the console the cleaned wash water travels by gravity to (4) smaller chambers located in the front of the console.

The water next flows through (4) sets of CELLOFOAM filters where emulsified oils are removed by the process of adsorption and held in the CELLOFOAM filters until it can be squeezed or washed out. The cleaned water can then be discharged to sewer by gravity or an optional discharge pump can be provided to pump the water away to sewer or to another system for further treatment as in a wash water filtration system for re-use.Operating on 115 VAC, this system uses a Submersible Sump Pump mounted inside a Barrel Filter to pump the water from the pit and into a set of large tanks mounted at the back of the console.

The rear tanks have oil coalescers which force free floating oils to float to the surface where the oil can be skimmed off through a bleed-valve and into a bucket or an optional oil collection barrel. Leaving the oil coalescing sections in the rear of the console the cleaned wash water travels by gravity to (4) smaller chambers located in the front of the console.